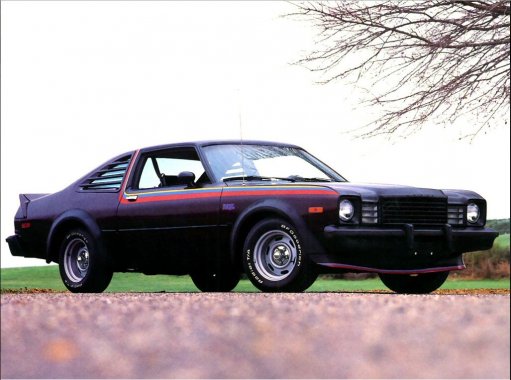

Aspen Super Coupe. For someone it is just a car. For someone it is a full package for driving. There are a lot of guys who'd buy it just for its looks alone. And admittedly, this street dream does exude a load of very heavy charm. See for yourself: Dark purple metallic paint with contrasty body side and lower rear panel striping and roof tape. Plus a flat-black finish for the hood, front fender tops, wheel flares, wiper arms, front and rear bumpers, spoilers, and racing mirrors. Why, it's enough to moisten the eye of any veteran tough car fan. But there's more. Quarter-window louvers. And those lovely big eight-inch-wide road wheels fitted with GR60*15 white letter Aramid fiber-belted radials. Just the kind you'd expect.

The vehicle was wind-tunnel tested to be aerodynamically sound in its fuel conservation potential as the complete aerodynamics development program included a wide range studies from drag reduction to crosswind stability, wind noise and ventilation performance. The effects of this testing resulted in softened front end contours, removal of drip troughs and helped shaped internal air flow ducting. Body engineering in the Aspen was executed using computer technology; unit body engineering was conducted by use of clear plastic stress models that showed up stress points before any sheet metal was formed. Weight reduction to provide maximum fuel economy was achieved through use of thinner glass, lighter weight side door beams and high-strength, low-alloy brackets and reinforcements that were four times as strong as conventional mild steel. A reduced number of stampings resulted in better panel fits and fewer welds. The Aspen had improved visibility and compared with other Dodge compacts, the Aspen provided a total glass area increase of 25% on two-door models and 33% on sedans.

Wheel alignment adjustments such as caster and camber could be made by removing plates over the wheel housings. The new isolated transverse suspension system was a substantial departure from the longitudinal torsion bars Chrysler had introduced in 1957 and used on all models since that year, until the release of the F-bodies. The transverse (side-to-side) bars weren't as geometrically favourable but saved space and weight. In addition, the new front suspension system was touted as giving a "big car ride" as the suspension had a low, or softer, fore and aft compliance which allowed the wheel to move rearward instead of straight up and down when the tire encountered an object, dampening the blow and rolling with the condition of the road. The two parallel torsion bars and an anti-sway bar were mounted forward of the front wheels, integrated into a spring-strut front suspension. These components were attached to a K-shaped structural cross-member. The K-shaped cross-member was isolated from the car body by four rubber mounts. This transverse torsion bar suspension was also incorporated into the M- and J-body cars. The conventional leaf spring rear suspension was also rubber-isolated, so there was no metal-to-metal path through which road noise or vibration can be transmitted to the body; even the steering column was isolated.